Following the launch of trove.scot in February 2025 we are now planning the retiral of some of our webservices. Canmore will be switched off on 24th June 2025. Information about the closure can be found on the HES website: Retiral of HES web services | Historic Environment Scotland

Edinburgh, Portobello, Pipe Street, Thistle Pottery

Pottery Works (18th Century)

Site Name Edinburgh, Portobello, Pipe Street, Thistle Pottery

Classification Pottery Works (18th Century)

Alternative Name(s) Bridge Street; Portobello Pottery; Rathbone Pottery; Waverley Pottery

Canmore ID 53824

Site Number NT37SW 172

NGR NT 30435 74255

NGR Description Centred NT 30435 74255

Datum OSGB36 - NGR

Permalink http://canmore.org.uk/site/53824

- Council Edinburgh, City Of

- Parish Edinburgh (Edinburgh, City Of)

- Former Region Lothian

- Former District City Of Edinburgh

- Former County Midlothian

NT37SW 172.00 centred 30435 74255

NT37SW 172.01 NT 30451 74262 and NT 30460 74256 Kilns

(Location cited as NT 304 742 and name as Portobello Pottery). Founded c. 1879. Formerly a complex of 1- and 2-storey brick and rubble buildings, some with pantiled roofs. The buildings have been demolished, leaving the two bottle kilns (dated 1906 and 1909) which are to be preserved as free-standing monuments.

J R Hume 1976.

Late 18th- and 19th-century buildings, single and two-storey, mostly of brick with pantiled roofs, partly replaced by asbestos. Two bottle-kilns remain, dated 1906 and 1909 respectively.

W Baird 1898; J A Fleming 1923; G D Hay and G P Stell 1986.

172.1 Two bottle-kilns dated 1906 and 1909 are the only visible remains of the Thistle Pottery. They have recently been restored and the flues and doorways blocked up with bricks.

Site recorded by GUARD during the Coastal Assessment Survey for Historic Scotland, 'The Firth of Forth from Dunbar to the Coast of Fife' 23rd February 1996.

NT 3047 7424 (centre) An evaluation was undertaken in October and November 2005 to locate and assess part of Portobello Harbour wall structure and recover pottery from deposits of kiln waste used for land reclamation, prior to a proposed development adjacent to the evaluation area.

The evaluation site is located on open ground on the SE side of two restored Scheduled pottery kilns (NT37SW 172.01) on the former site of the Waverley Pottery. Based on cartographic evidence, two trenches were located so as to overlie the projected line of the E wall of Portobello Harbour channel. The two trenches were handexcavated, one reaching a maximum sondage depth of 2.2m and then probed with an auger for a further 0.33m.

Excavation revealed that, below topsoil, waste from the pottery had been dumped to infill and level the ground. The dumps comprised clinker, ash, cinders, bricks and cobbles as well as silt, gravel, sand and clay. Pottery sherds recovered from the dumping date from the early to late 19th century. Tip lines formed by the dumping descended to the NW, tentatively indicating dumping over the E quayside and into the channel between the harbour walls.

The pottery waste dumping overlay loose sand containing early 19th-century pottery, large pantile fragments, and cobbles. No structural evidence of the harbour was located. It was concluded that the E harbour wall may lie below trench depth, be located further to the E (perhaps under Pipe Lane), or the stonework has been robbed out at this location.

Archive to be deposited in NMRS.

Sponsor: Lothian Amusements Ltd.

R Cachart 2005.

Publication Account (1986)

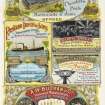

Portobello was one of the principal centres of the ceramic industry on the S bank of the River Forth, and at their closure in 1972 these premises of the Thistle Pottery of A W Buchan & Company Ltd, formerly known as the Portobello or Waverley Pottery, probably const ituted the last complete industrial pottery in Scotland . First established in about 1770, the pottery came into the ownership of the Buchan family in 1867. It was substantially rebuilt and extended after 1879, partly covering the area of an infilled 18th century harbour which was originally built to serve Rathbone's Midlothian Pottery nearby. At the date of survey it manufactured a decorated and buff-glazed stoneware using ball-clay and china-clay imported from Devon and Cornwall.

Much of the plant and machinery was of comparatively recent date but included a steam-powered pan-mill for crushing faulty or impure ware. It had a cast-iron pan 7 ft (2.13mm) in diameter which was driven by an upright shaft and overhead gearing; it was rotated beneath a pair of solid iron-rimmed sandstone wheels 3 ft 6 in (1.07m) in diameter and 1ft (0.31m) wide. The earliest identifiable feature of structural interest was a timber king-post roof-structure of about 1800; this was incorporated in a two-storeyed brick building which had a two-bay arcaded and gabled frontage to Harbour Road.

Three coal-fired bottle-kilns of traditional design were installed in 1903, 1906 and 1909, and, a lthough replaced by an electric furnace in 1956, the two latest kilns still surv ived at the clos ure of the works. At that time only the 1909 kiln was access ible for detailed inspection and measurement.

Constructed of a yellowish-coloured brick laid in an English garden-wall bond, the circular kiln stands to a height of 39 ft (11.89m). It has an angular bottle profile, slightly narrower in the neck than its neighbour, and the drip-course at the top is ornamented with a dentil-band. At the base the kiln measures 23 ft 3 in (7.09m) in diameter over walls 3 ft (0.91m) thick. Ten arched furnace-holes with associated ash-pits are formed in the perimeter of the kiln and correspond with dwarf 'bag-walls' inside. In the initial firing-process a circular vent in the saucer-domed roof of the kiln-chamber was left open, thus creating an updraught; the damper was then closed and a down-draught was induced through a circular aperture in the centre of the kiln floor, passing beneath a tunnelled floor, upwards through mural flues and emerging around the outer rim of the dome. Each firing consumed about 13-14 tons (c. 13.72 tonnes) of coal, and, including a cooling period, lasted for about two and a half days. The kiln had a capacity for about 130 piles of saggars.

Information from ‘Monuments of Industry: An Illustrated Historical Record’, (1986).

Archaeological Evaluation (December 2006)

NT 3045 7430 (evaluation). An archaeological evaluation was undertaken during December 2006 on a grassed verge at Harbour Place, Portobello, to identify any surviving elements of the former Thistle Pottery factory.

This work consisted of three test pits in the grassed verge. No archaeological features were identified associated with the pottery works. However, the topsoil of each trench contained numerous saggar and pottery sherds and an 18th-century water pipe.

Archive and report to be deposited with RCAHMS. Report deposited with City of Edinburgh SMR.

Funder: City of Edinburgh Council.