Pricing Change

New pricing for orders of material from this site will come into place shortly. Charges for supply of digital images, digitisation on demand, prints and licensing will be altered.

Ellon, Wateridgemuir

Water Wheel (Period Unassigned)

Site Name Ellon, Wateridgemuir

Classification Water Wheel (Period Unassigned)

Canmore ID 290230

Site Number NJ92NE 128.01

NGR NJ 95407 26438

NGR Description centred

Datum OSGB36 - NGR

Permalink http://canmore.org.uk/site/290230

- Council Aberdeenshire

- Parish Logie Buchan

- Former Region Grampian

- Former District Gordon

- Former County Aberdeenshire

NJ92NE 128 95369 26419

Wateridgemuir Farm lies approximately 3.5 km South of Ellon. It is a large E plan farm steading comprising a cart shed and granary on the main NW range with threshing barn and cow sheds forming the three perpendicular ranges. To the NE of the steading survives the remains of a large overshot metal waterwheel (4.5m diameter x 1m wide) in an underground cavern which is fed by a lade from the nearby millpond, evidence of which still survives. Visited by RCAHMS (MMD & EAL) 15 August 2007.

Note (7 October 2007)

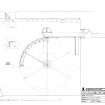

The subterranean waterwheel pit is located at the NE end of the Wateridgemuir steading buildings. It measures 4m in width, 12.2m in height and 13.2m in length. It is of rubble construction with a capped roof of longitudinally placed granite slabs (see DP 035675). There is an access ledge 0.5m in width along the length of the pit running N-E presumably to allow for repair. The modern ingress is through a trapdoor.

The tail race is in line with the wheel, measuring 0.8m in height, and is somewhat narrower than the wheel creating a syphon effect. The waterwheel pit appears to date from the re-building of the site in the mid 19th century at which time the buildings were realigned and the mill pond was constructed on what was formerly pasture land (Wolrige-Gordon Papers, Plan of Wateridgemuir Farm, Ellon, MSAcc 040, Box 5, Bundle 5, 1824 (farms)/1852 (farmland), University of Aberdeen, Special Libraries and Archives).

There is anecdotal evidence that the wheel was still in use in the 1970s (pers. comm. from Mr Sutherland, site developer, October 2007).

The site was recorded in advance of conversion to dwellings and the ‘soft filling’ of the waterwheel pit.

See RCAHMS DC 48442, DC 48443, DC 48444, DC 48445.

WATERWHEEL

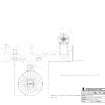

The water was taken by a wooden penstock/launder from the lade (measuring 3.2 m in length by 0.8m in width and 0.4m in height; see DP035622) to a point in the wheel which caused it to rotate on its axle away from the flow of water from the lade. This is referred to as an overshot or high breast wheel (see DC DP48445 and DP035612). The waterwheel, measuring 4.3m (10.5 feet) in diameter by 1.2m (4 feet) in width, has two cast-iron rings. It originally had six cast-iron arms, 36 wooden bucket-floats (all but gone, see DP035614) fitted into the angled cants in the shroud plates, a wooden sole-plate, a square axle and rim-gear teeth.

Little survives of the system operated from the adjacent steading building that controlled the flow of water to the wheel and thus the speed of the machinery. This consisted originally of a wooden lever (extant) protruding through an aperture in the NE wall of the former milking byre. This aperture measured 0.10m in width by 0.7m in height (see DC48444, DP035680). The lever would have been attached to a metal rod that would in turn have been attached to a trapdoor (opening away from the wheel) in the launder. By moving the lever up and down, the trapdoor could be opened and closed allowing the water to run into the wheel pit without hitting the buckets of the wheel (see DC48445).

The rim-gear teeth rotated as the wheel rotated driving a cast-iron spur wheel and pinion which it turn may have rotated a belt pulley wheel (see DC48443, DC48444 (section X-X1), DP035620) which in turn may have connected with a small belt pulley wheel on a triple pulley wheel system on a single shaft within the interior of the adjacent steading building. This machinery would have been enclosed in a wooden ‘cupboard’ (now gone) for protection against damage and the elements. This machinery could have possibly also have operated threshing equipment within the steading building.

There is also evidence in the wheel pit wall of bearing box remains suggesting an auxiliary arrangement of another spur wheel or wheels (see DC48455), which potentially operated further equipment in the steading building above and adjacent to the wheel pit. The larger of these additional spur wheels could have been driven direct from the waterwheel rim and this in turn meshed with a smaller wheel below and to one side. There is an aperture in the steading wall measuring 1.0m in width and 1.8m in height directly above the evidence of bearing box remains. The triple pulley wheel mentioned above sits directly above and offset within the building above but appears to be later and unrelated to the additional spur wheel evidence and the wall aperture.

Visited by RCAHMS (MMD, JB, HS), October 2007.